1. Introduction to Huansi

For fifteen years, Huansi has adhered to the philosophy of dedicating itself to the informatization of the textile and apparel industry. This dedication has established Huansi's position as a leader in the field of textile and apparel informatization and has cemented its indispensable role in the industrial upgrade and corporate transformation within the textile and apparel sector.

Huansi is the only company in China that covers the entire textile and apparel industry chain with its informatization services. It is also the largest technology company in China focusing on textile and apparel informatization. Huansi has accumulated nearly a thousand informatization cases for textile and apparel enterprises, including nearly 50 listed companies such as Erdos, Shandong Ruyi, Luolai Home Textiles, Youngor, and Anta. Additionally, it serves 100 of the top 500 textile and apparel companies and 200 comprehensive large and medium-sized textile group enterprises.

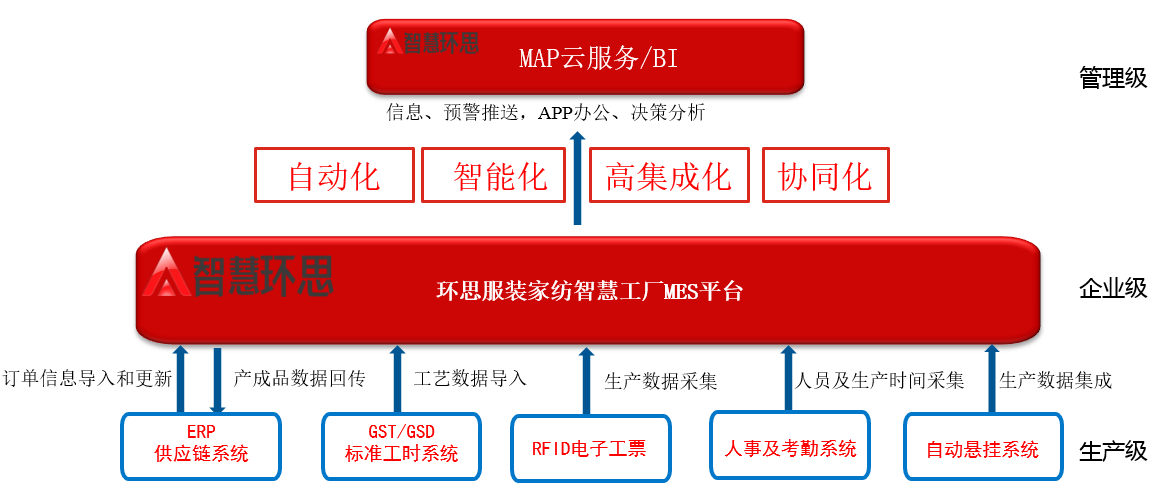

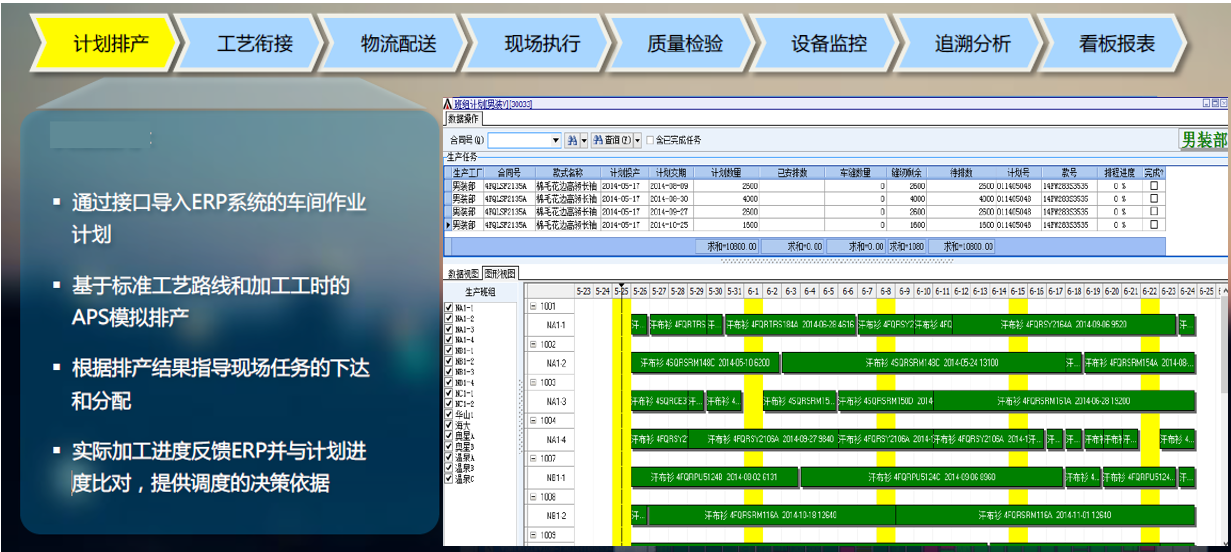

For over 10 years, Huansi has focused on the informatization of the textile and apparel industry. Leveraging advanced management philosophies and control models from several excellent apparel and home textile enterprises, Huansi has designed and developed the Huansi Apparel Smart Factory MES (Manufacturing Execution System). This system fully utilizes IoT technologies such as barcodes, RFID (Radio Frequency Identification), and sensors to achieve the digital definition and storage of personnel, materials, equipment, and processes during production execution. This digital integration ensures that each production unit becomes a networked software organization, effectively addressing key challenges in the production process, including scientific scheduling, data collection, standard process guidance, proactive verification, reflexive control, and piece-rate wage calculation.

The Huansi Smart Factory MES System supports various production modes such as single-piece flow, bundle flow, process flow, and Y-shaped mixed flow. It optimizes scheduling through real-time production data, improves the first-pass yield, and automatically calculates workers' piece-rate output wages. This system effectively enhances workers' and machines' skills, efficiency, and productivity, thus improving overall production efficiency.

The Huansi Apparel and Home Textile MES System incorporates various data models to analyze and process massive amounts of industrial data. It simulates human brain thinking and response through the system and quickly pushes and responds via internet technology. This assists production management personnel in making scientific decisions and reducing production and operational risks.

Illustrations:

II. Product Advantages of Huansi Apparel Smart Factory MES Platform

1. Platform Deployment with Excellent Stability, Openness, and Scalability

Illustrations:

3. Leveraging Barcode and RFID IoT Technology for Comprehensive Product Manufacturing Traceability

Digitalization and Networking: Utilizing barcode, RFID, and IoT barcode technology to digitize and network personnel, equipment, and materials. This allows for comprehensive monitoring and traceability from raw materials to semi-finished products to finished products, thereby enhancing on-site management levels, improving the first-pass yield of finished products, and boosting production efficiency.

Enhanced On-Site Management: By strengthening on-site management, the system increases factory transparency and achieves flat management. It provides accurate and systematic data for each production process on the assembly line, enabling traceability from raw materials to semi-finished and finished products. This promotes meticulous production organization management, improves the quality of manufactured products, and reduces the risk of quality issues and delivery delays.