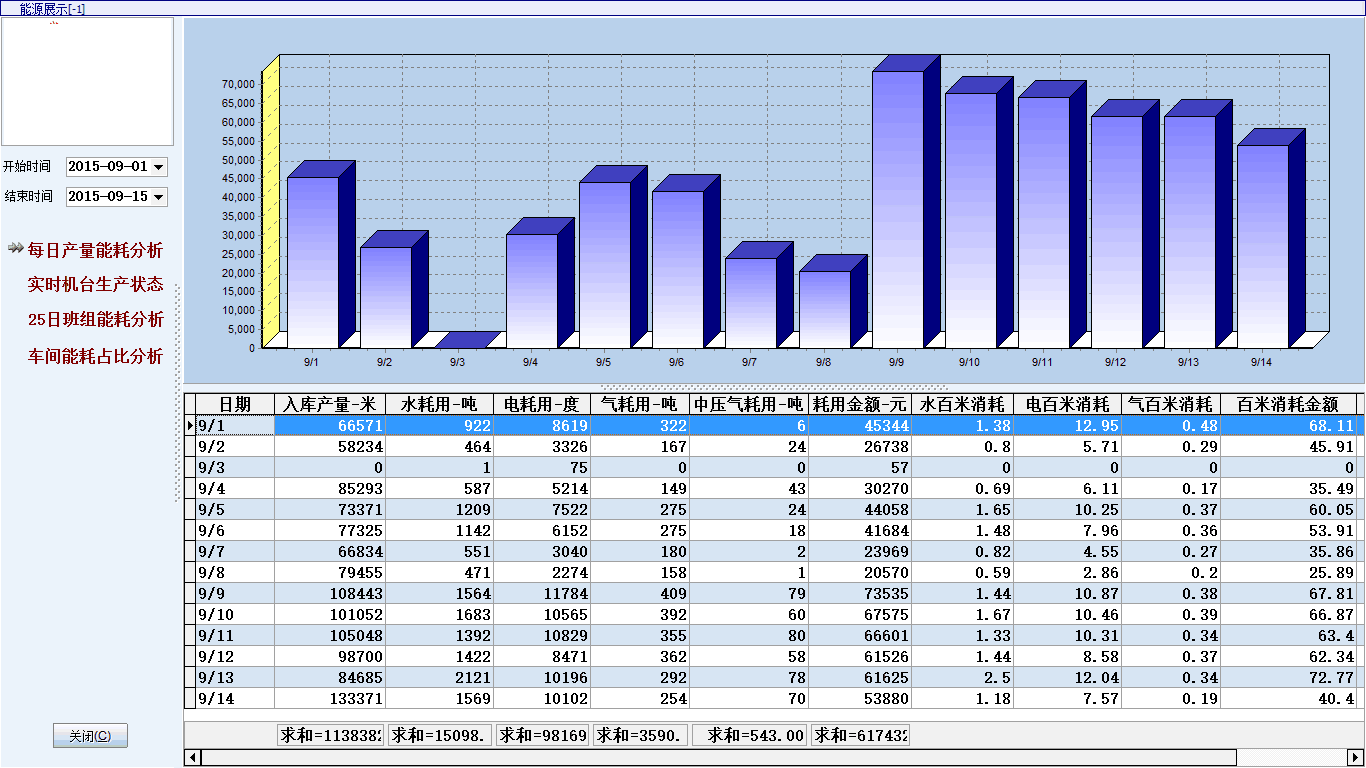

1. Achieving Real-Time Energy Data Collection and Control

Improving the utilization rate of production equipment in the workshop is a constant goal for enterprises. By monitoring the machines during the production process and collecting key equipment data, the system can:

3. Achieving Online Monitoring and Control of Workshop Equipment Parameters

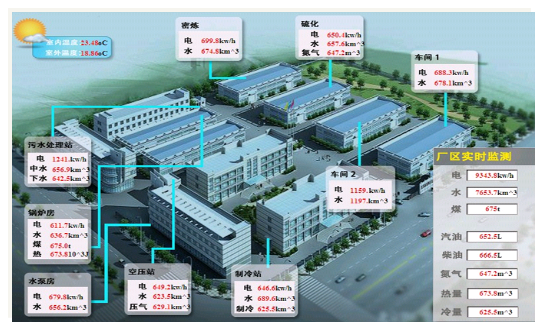

The system establishes an online monitoring platform through network informatization, digitization, and intelligence. This includes:

Integration of Various Processes: Incorporating customer samples, computer color matching, sample prescriptions, customer-approved samples, dye formulations, large-scale production processes, and dye addition systems into the platform.

Standard Process Archives: Technical departments compile standard process archives for regular products.

Reduction of Errors and Redundancy: Minimizes human repetitive labor, wrong formulations, incorrect dye weighing, incorrect tank loading, disorderly process changes, and variations due to different employee responsibility levels.

4. Achieving Real-Time Logistics Tracking and Machine Production Reporting

Unique Identification: Use barcodes (1D, 2D) and RFID cards (radio frequency) to uniquely identify batches of fabrics (including raw materials, semi-finished, and finished products).

Real-Time Data Collection: Collect real-time transfer information for each production segment through various on-site collection devices.

ERP System Integration: Interact with the ERP system to monitor the location of any batch of fabric in real-time.

5. Achieving Timely Equipment Maintenance Management

Real-Time Monitoring: Real-time monitoring of machine operation status by interfacing with equipment manufacturers' communication ports.

Dynamic Display: Display dynamic data such as machine speed, temperature, current value, and tension parameters.

Preemptive Fault Detection: Helps equipment managers predict machine anomalies, reducing sudden stoppages due to equipment failures.

6. Achieving Real-Time Production Dashboard Management

Real-Time Information Transmission: Use the real-time dashboard management subsystem to convey and feedback workshop information.

Immediate Alerts: Provide real-time alerts, allowing managers to intervene and adjust promptly.

Proactive Control: Transform post-event control into preemptive control, addressing issues at their inception.